Revolutionizing Efficiency: The Fully Automatic Hanging Plating Production Line

Release time:

Mar 31,2025

The Future of Manufacturing is Here

Hey there, folks! Buckle up, because we’re diving into the exciting world of manufacturing innovations. The buzzword on everyone’s lips? You guessed it—the fully automatic hanging plating production line. This state-of-the-art technology is not just a game-changer; it’s a whole new ball game!

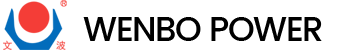

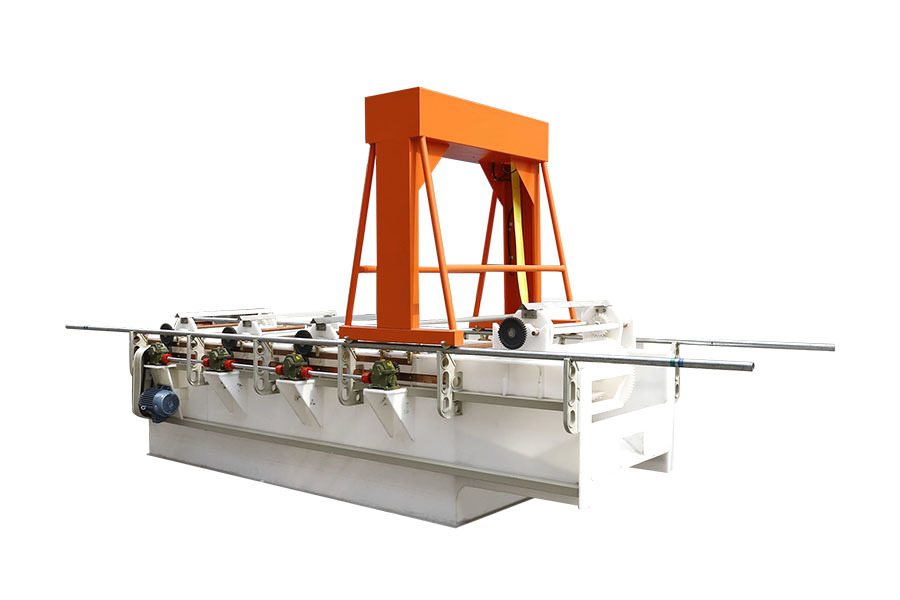

What is a Fully Automatic Hanging Plating Production Line?

Let’s break it down, shall we? At its core, this production line automates the plating process, allowing manufacturers to hang items for efficient coating. This means less manual labor, fewer errors, and a much smoother operation. It’s like having a well-oiled machine that runs itself while you grab a cup of coffee!

Why Go Fully Automatic?

So, why should companies jump on the bandwagon? Well, for starters, the fully automatic hanging plating production line boosts productivity significantly. With automation, the production time decreases, and consistency in quality skyrockets. Talk about a win-win!

Cost-Effective and Eco-Friendly

Another bonus? It’s cost-effective! By minimizing labor costs and maximizing output, businesses can save a pretty penny. And let’s not forget about the eco-friendly aspect. These machines often use less energy and generate less waste, making them a sustainable choice for the environment-conscious.

How Does It Work?

Now, you might be wondering, "How does this technological marvel actually work?" Well, it’s quite simple! Items are hung on a conveyor system, which then moves them through various plating stations. Each station is equipped with specialized tools that apply the plating uniformly. It’s like a roller coaster ride for your products, ensuring they reach their destination all decked out!

Flexibility and Customization

One of the standout features of the fully automatic hanging plating production line is its flexibility. Manufacturers can customize the plating process to suit different products, allowing for a wide range of applications. Whether you're plating automotive parts or decorative items, this system has got you covered!

Challenges and Considerations

Of course, it’s not all sunshine and rainbows. Transitioning to a fully automatic system can be a hefty investment upfront. Companies need to weigh the costs against long-term savings. But, hey, Rome wasn’t built in a day, right? With the right planning and a clear vision, the transition can be smooth sailing.

Training and Expertise

Moreover, employees may require training to operate the new machinery effectively. Investing in skilled labor is crucial, ensuring that the system runs like a charm. After all, you wouldn’t drive a Ferrari without knowing how to handle the wheel!

The Bottom Line

In a nutshell, the fully automatic hanging plating production line is reshaping the landscape of manufacturing. Its ability to enhance productivity, reduce costs, and promote sustainability makes it a top contender for any business looking to modernize. So, if you’re in the manufacturing game, it might be time to consider this innovative solution. Who knows? It could be the key to unlocking your business’s true potential!

Join the Revolution!

So, what are you waiting for? Dive into the future of manufacturing with the fully automatic hanging plating production line and watch your business soar. Let’s embrace the revolution and ride the wave of innovation together!

Blog