Water Spray Method for Electroplating Waste Gas Treatment

Release time:

Jul 25,2024

I believe everyone has some understanding of the electroplating industry and knows that it is a highly polluting industry. In order to establish a clean environment, the industrial waste gas generated by electroplating must be treated quickly to ensure that there is no emission of polluting waste gas. People have come up with several methods of waste gas treatment. Today, we will talk in detail about the water spray method in the treatment of electroplating waste gas.

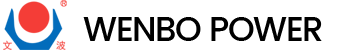

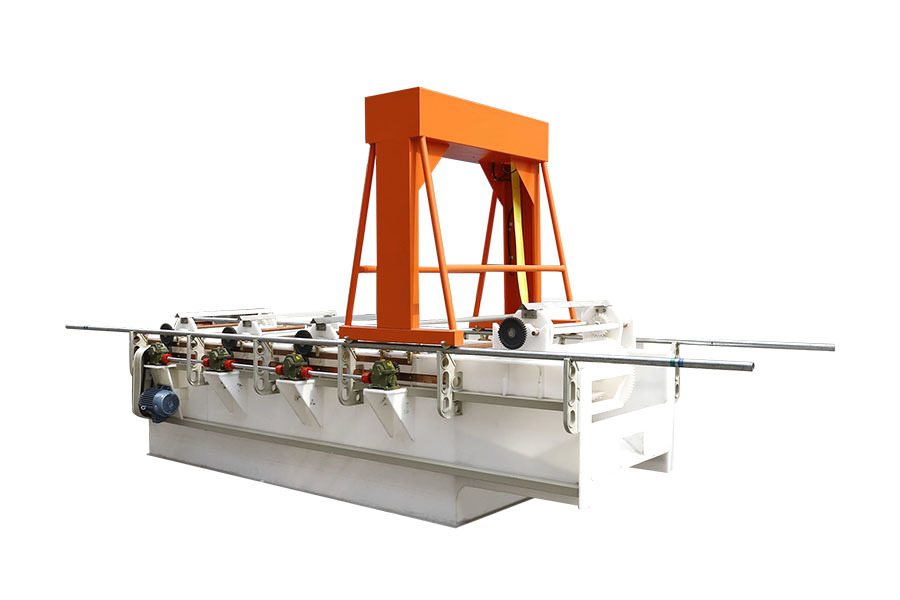

The water spray method has a wide range of applications in the treatment of air pollution, and is also used in the spraying process. It mainly sprays exhaust gas with water to settle the water-soluble or large particle components in the exhaust gas, achieving the goal of separating pollutants from clean gases.

Its advantage is that water resources are easily available and can be reused after filtration and precipitation, which can minimize the waste of water resources. The water spray method has a relatively high efficiency in treating large particle components and is often used as a pre-treatment method for exhaust gas treatment. Of course, the spray method also has its shortcomings, that is, although the process is simple and easy to operate, it is not suitable for dry material recycling. If the problem of water circulation cannot be handled well, it will cause secondary pollution.

Blog