What is a rolling plating equipment production line

Release time:

Jul 25,2024

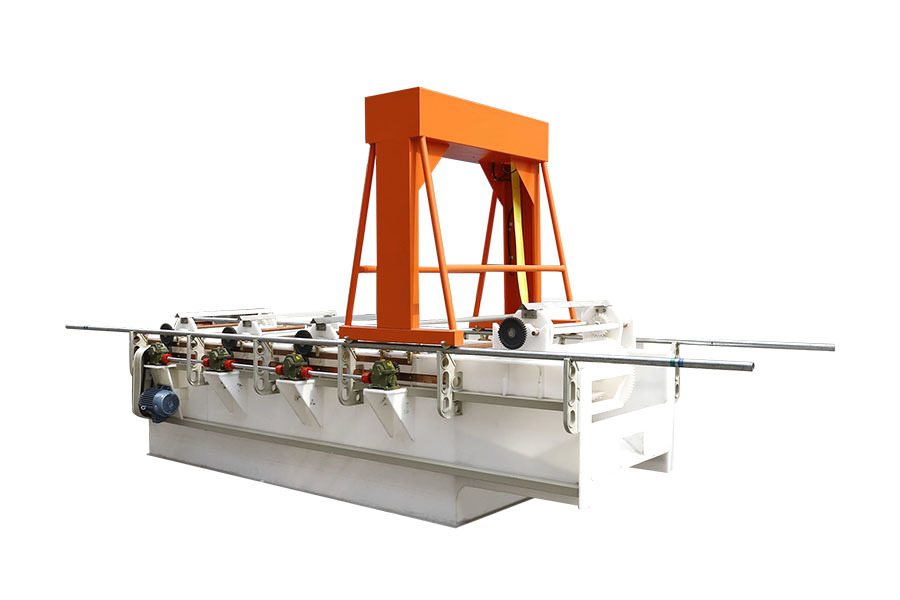

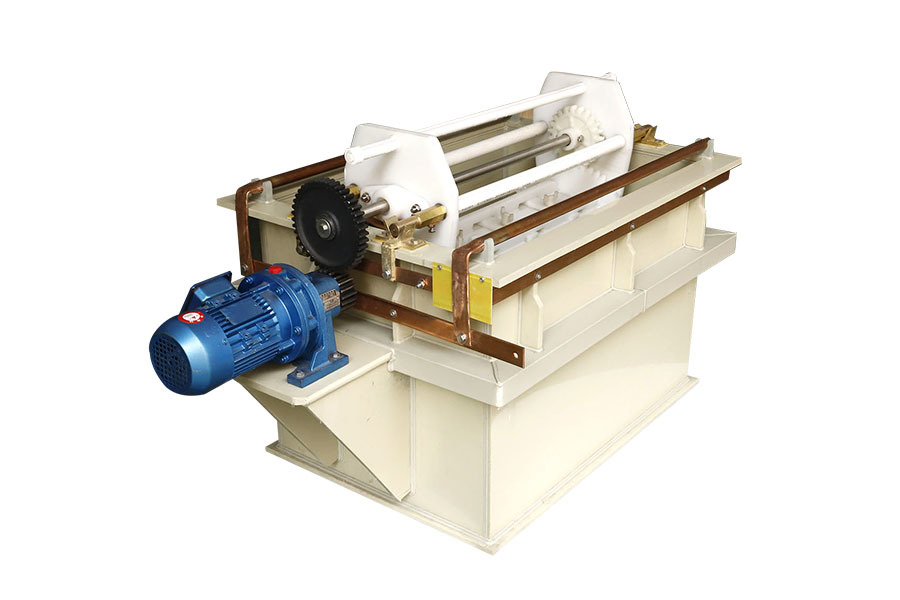

The typical rolling plating process is as follows: small parts that have undergone pre plating treatment are loaded into a drum, and the cathode conductive device inside the drum is tightly pressed by the weight of the parts to ensure the smooth transmission of the required current when the parts are plated. At the same time, the main metal ions are reduced to a metal coating on the surface of the parts under the action of an electric field. Fresh solution outside the drum is continuously replenished into the drum through countless small holes on the drum wall plate, and the old liquid and hydrogen gas generated during the plating process inside the drum are also discharged outside the drum through these small holes.

Strictly speaking, roller plating is called drum electroplating. It is a electroplating process that places a certain number of small parts in a dedicated drum and deposits various metal or alloy coatings on the surface of the parts in an indirect conductive manner while rolling, in order to achieve surface protection, decoration, and various functional purposes. The typical rolling plating process is as follows: small parts that have undergone pre plating treatment are loaded into a drum, and the cathode conductive device inside the drum is tightly pressed by the weight of the parts to ensure the smooth transmission of the required current when the parts are plated. At the same time, the main metal ions are reduced to a metal coating on the surface of the parts under the action of an electric field. Fresh solution outside the drum is continuously replenished into the drum through countless small holes on the drum wall plate, and the old liquid and hydrogen gas generated during the plating process inside the drum are also discharged outside the drum through these small holes.

Blog