Revolutionizing Manufacturing: The Fully Automatic Hanging Plating Production Line

Release time:

Mar 31,2025

Introduction to Innovation

Have you ever wondered how modern factories churn out products with such speed and precision? Well, hold onto your hats because we’re diving into the fascinating world of manufacturing, specifically focusing on the Fully automatic hanging plating production line. This technological marvel is not just a mouthful; it's a game-changer!

What is a Fully Automatic Hanging Plating Production Line?

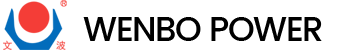

In the simplest terms, the fully automatic hanging plating production line is a sophisticated system designed to automate the plating process, allowing manufacturers to coat products efficiently and uniformly. Imagine a conveyor belt where items hang, getting coated in a seamless, synchronized flow. It's like watching a well-choreographed dance, with each piece performing its role flawlessly.

Why Go Fully Automatic?

Let’s be real—manual processes can be a real pain in the neck. They’re slow, prone to errors, and often lead to inconsistent results. By embracing a fully automatic approach, businesses can:

- Boost Efficiency: With automation, the production line can work around the clock, significantly increasing output.

- Reduce Labor Costs: Fewer hands are needed on deck, leading to lower wage expenses.

- Enhance Quality: Consistency is key in manufacturing; automation minimizes the risk of human error.

How It Works

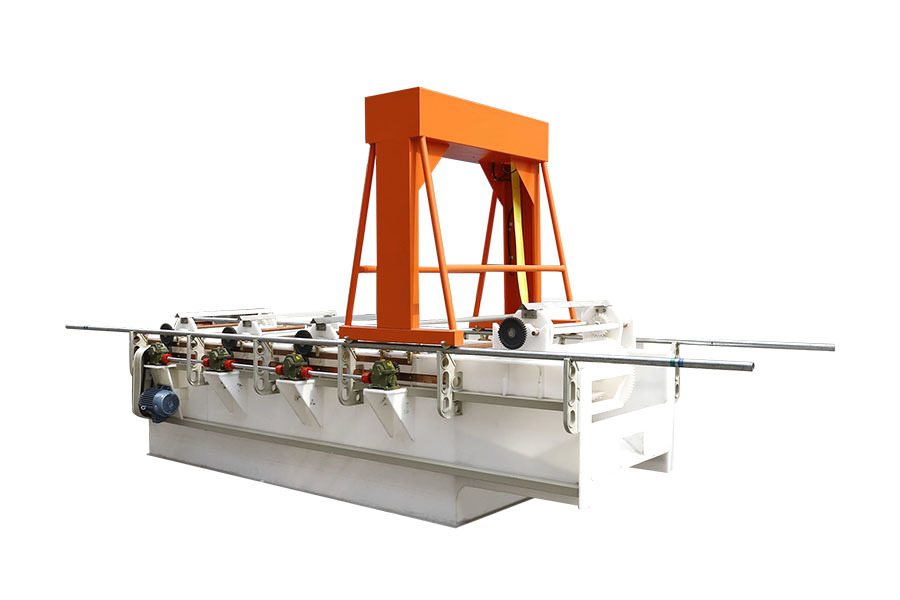

Alright, let’s break it down! The structure of a fully automatic hanging plating production line typically involves several key components:

1. Pre-Treatment Section

Before any plating happens, items undergo a rigorous pre-treatment process. This stage ensures that surfaces are clean and ready for that shiny coat.

2. Plating Zone

Next up, the items glide into the plating zone, where a series of automated arms dip them into plating baths. It’s like a luxury spa day for your products!

3. Drying and Curing

Once plated, the items move on to drying and curing phases. Here, they’re heated to ensure the finish sets properly. This step is crucial for durability.

4. Quality Control

Finally, quality control steps in to make sure everything meets industry standards. Any imperfections? No problem! This system’s equipped to handle that.

The Industry Impact

The rise of the fully automatic hanging plating production line is reshaping industries across the board—from automotive to electronics. Companies that invest in this technology are seeing:

- Faster Turnaround Times: No more waiting around for orders to be completed!

- Increased Scalability: Businesses can easily scale up production to meet demand without compromising quality.

- Environmental Benefits: Automated systems often use resources more efficiently, reducing waste.

Challenges Ahead

Of course, it’s not all sunshine and rainbows. Implementing a fully automatic hanging plating production line comes with its own set of challenges. Initial costs can be high, and the technology requires skilled personnel to manage and maintain. But hey, no pain, no gain, right?

The Future Looks Bright

As the industry continues to evolve, the fully automatic hanging plating production line will undoubtedly play a pivotal role in driving innovation and efficiency. With advancements in AI and robotics, who knows what the future holds!

Conclusion

To wrap it all up, the fully automatic hanging plating production line is not just a trend; it’s the future of manufacturing. By automating processes, businesses can enhance efficiency, reduce costs, and improve product quality. So, if you’re in the industry, it’s time to consider making the shift. After all, it’s a brave new world out there!

Blog