Maintenance and upkeep of electroplating production line

Release time:

Jul 25,2024

1. Tank body

The main difference between horizontal electroplating lines and vertical lifting electroplating lines lies in the transportation method of the products, so the maintenance and upkeep methods for the tank body are basically the same. Generally, each water washing tank needs to be cleaned once every 7 days, and the acid tank needs to be cleaned once and the tank solution needs to be replaced; If there is a sprinkler installed in the tank, it is necessary to check whether there is any blockage. If there is any blockage, it should be cleared in a timely manner; Clean the conductive seat and anode contact position on the plating tank once, using a cloth to wipe and sandpaper to polish; Inspect the titanium basket of the plating tank and promptly replace any damaged titanium basket bags. Clean the electrode protection bag approximately once every 90 days, and filter and clean the tank solution with activated carbon around 120 days to remove impurities from the tank solution.

The replacement of the tank liquid requires trial production of the current mode, and production can only be carried out after the performance is stable.

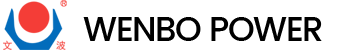

2. Maintenance and upkeep of the horizontal electroplating line conveyor device

The conveying device used in the horizontal electroplating line is parallel conveying, which uses the parallel conveying method to transport the products to each tank. Generally, the conveying rod of the horizontal electroplating line should be cleaned once every 7 days to remove any foreign objects adhering to it and ensure that the conductive rod is in good condition during transportation; Check the linkage for looseness. Check the walking wheels every 180 days for wear and tear, and replace them promptly to ensure that there is no jamming during transportation; Conduct an inspection of the transmission shaft and the entire transmission system, and promptly repair any problems found.

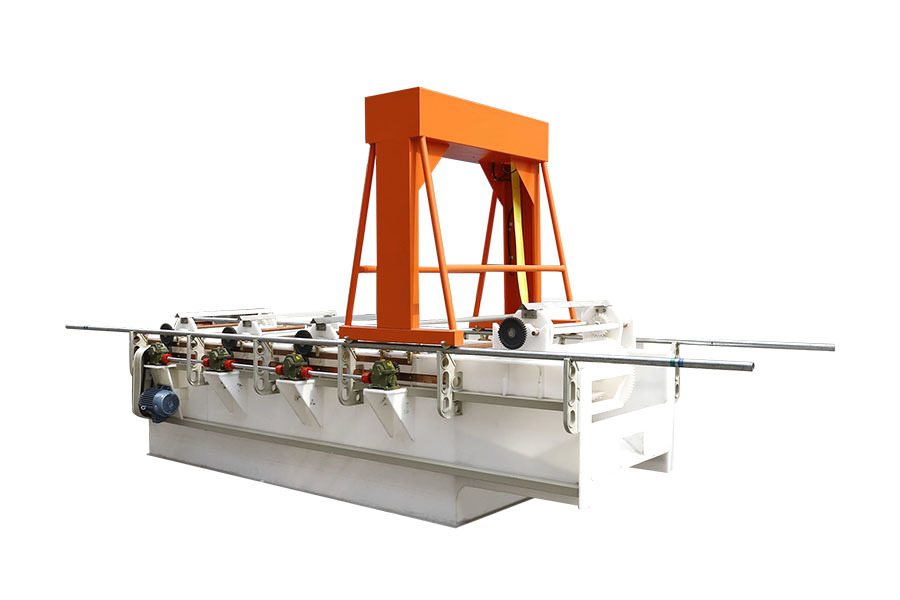

3. Maintenance and upkeep of the vibration mechanism of the vertical lifting electroplating line

The conveying device used in the vertical lifting electroplating line is the lifting vibration remote conveying, which uses the lifting conveying method to transport the products to various tanks. On the vertical lifting electroplating line, in order to ensure the uniformity and effect of electroplating, a vibration swing device will be designed, and there will be a vibration swing mechanism on the tank body. Check whether the reducer is running normally and whether its fastening is good in about 30 days. Check the fastening of the vibration motor bolts and the wear of the vibration rubber. For those with severe wear, they should be replaced in a timely manner. Check the contact status of the power lines inside the junction box for about 180 days. Replace the power lines with melted or aged insulation layers in a timely manner to ensure the insulation between the power lines; Inspect all bearings on the vibration mechanism, apply lubricating grease, and replace severely worn bearings in a timely manner. Clean the operating crane and hanging equipment once a week (without dismantling), using a cloth to wipe and sandpaper to polish. Inspect the hanging equipment once every 30 days to check for any damage; Inspect and maintain all motors of the vehicle to ensure they can operate normally. Conduct a thorough cleaning and maintenance of the vehicle and its attachments every 180 days, and remove the attachments from the vehicle for cleaning.

4. Maintenance and upkeep of the circulating filtration device

Check the filter cartridge of the circulating filtration device once every 7 days to see if there is any leakage. Clean or replace the filter cotton core approximately every 15 days. The filter carbon core needs to be replaced in about 30 days to ensure the quality of filtration and the flow rate of the filter machine; Clean the filter pump once, clean the filter hood and filter mesh of the air pump. Check the contact condition of the pump motor power cord connector in about 30 days. If there is any looseness or aging of the wire, it should be dealt with in a timely manner to ensure good contact and safe insulation, and protect the motor.

5. Maintenance and upkeep of equipment around electroplating production lines

Check the output power of all power sources within 7 days; Inspect, remove dust, clean, and protect the heat dissipation effect of the power supply, electrical control cooling fans, and radiators. Inspect all electrical components within approximately 30 days and replace them promptly if there is any damage or corrosion; Check all connectors, and promptly repair any poor contact, loose connections, or solder joints. Replace any corroded or damaged connectors in a timely manner; Check all contactors and relays, and replace them promptly if there is poor contact or adhesion of the contacts; Check the main parameters of components such as capacitors, reactors, and resistors. If any abnormalities occur, replace them as soon as possible. Check and calibrate the automatic feeding system every 7 days or so. Clean the scale and dirt on the electric heater in about 7 days to prevent the internal temperature of the electric heater from being too high.

6. Maintenance and upkeep of pipelines

Inspect each water and gas pipeline system approximately every 7 days to check for any signs of leakage or leakage. Any pipelines that experience leakage or leakage should be promptly repaired and replaced.

7. Maintenance before long-term shutdown

If there is a planned long-term shutdown of electroplating equipment, maintenance should be carried out on the equipment to prevent corrosion and aging during the long-term shutdown process. To ensure that the ground is clean and kept dry, and to keep the machine, tank, crane, and hanging equipment clean and dry; All motors should be wrapped in plastic wrap for protection; All bearings are injected with lubricating grease and undergo rust prevention treatment; All the chemicals in the pipelines should be thoroughly drained; Clean the liquid in the filter barrel of the filter machine; Remove the filter element from the filter and clean it thoroughly; All heaters inside the tank should be cleaned, free of dirt, and kept dry.

Blog