Current Development Status of Electroplating Equipment Industry

Release time:

Jul 25,2024

On the basis of immersion galvanizing process, a comparative study was conducted on alkaline zincate electroplating galvanizing process and pyrophosphate electroplating galvanizing process. Electroplating production line: The electroplating production process generates some corrosive gases, and most of the raw materials used in production are acidic and alkaline substances, which are highly corrosive. If the electroplating equipment is operated in such a working environment for a long time, it will be corroded to varying degrees, inevitably leading to problems such as line aging, track erosion, and decreased mechanical lubrication, resulting in pipeline and tank leakage, signal failure of the transmission system, and misalignment of train operation.

If these electroplating wastewater do not meet the discharge standards and enter the environment directly, it will inevitably cause widespread and severe harm to the ecological environment and human beings. The result will cause the plated parts being produced to stay in the air or in a certain plating solution for a long time, resulting in uneven coating thickness, brittleness, and reduced bonding force. The quality of electroplating wastewater is complex, involving various heavy metal ions and cyanides, which pose a great threat to human health.

Using a pyrophosphate zinc plating layer as the bottom layer, followed by alkaline zincate thickening zinc plating, can effectively improve the glossiness and corrosion resistance of the zinc coating while reducing costs. The electroplating industry is an important processing industry and an essential means of product processing in many industries such as machinery, electronics, instruments, meters, light industry, aerospace, etc. PP board automatic welding equipment.

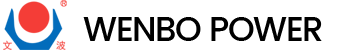

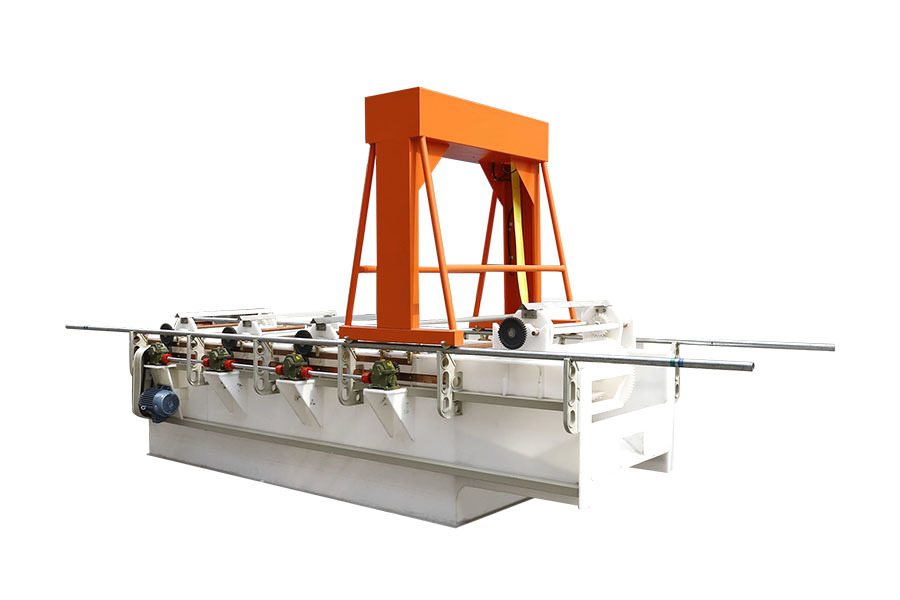

Electroplating equipment is a combination of plating tanks, parts lifting and transportation devices, electrical control devices, power equipment, filtration equipment, detection instruments, heating and cooling devices, air stirring equipment, etc. according to certain electroplating process requirements. It automatically completes the entire electroplating process through mechanical and electrical devices, with high production efficiency and consistent product quality.

The electronic electroplating industry is also one of the key industries for controlling heavy metal pollution in Jiangsu Province. The wastewater discharged during its production process poses a serious threat to the ecological environment along the lake. Currently, the electronic electroplating wastewater treatment technology with chemical precipitation, biochemical treatment, and membrane separation technology as the core units still has great room for improvement.

Blog