The influence of electroplating equipment on electroplating quality

Release time:

Jul 25,2024

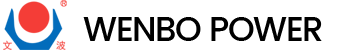

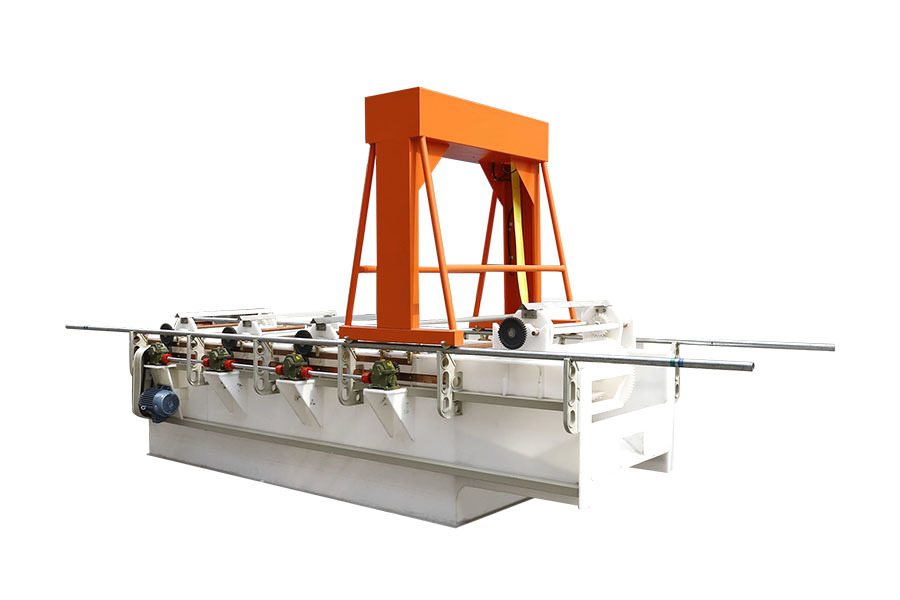

Electroplating equipment is a combination of plating tanks, plating parts lifting and transportation devices, electrical control devices, power equipment, filtration equipment, detection instruments, heating and cooling devices, air stirring equipment, etc. according to certain electroplating process requirements. It automatically completes all the electroplating process requirements through mechanical and electrical devices, with high production efficiency and stable product quality. Waste disposal of environmental protection equipment.

Electroplating production line: The electroplating production process generates some corrosive gases, and most of the raw materials used in production are acidic or alkaline substances, which are highly corrosive. If the production equipment operates in such a working environment for a long time, it will corrode to varying degrees, inevitably leading to problems such as line aging, track corrosion, and decreased mechanical lubrication, resulting in pipeline and tank leakage, power transmission system signal failure, and train operation misalignment. The result will be that the plated parts being produced will stay in the air or in a certain plating solution for a long time, causing problems such as uneven coating thickness, brittleness, and reduced adhesion.

Blog