PRODUCT

Dryer

Depending on the user's part processing, the barrel diameter of the inner barrel can be selected according to the size requirements.

Classification:

Introduction

Product Information

Main Features:

This product combines centrifugal drying and heating and drying into one body, and a built-in stainless steel drum makes you feel more convenient during use.

Depending on the user's part processing, the barrel diameter of the inner barrel can be selected according to the size requirements.

Main Features:

Stainless Steel

Screws Lid, Easy To Pen It

Stainless Steel Net Drum

Strong Anti-rust Ability

Foot Switch

Operate With Spared Hands

Product Instructions

1. Check the joint of the machine power supply and the fixed position of the drum is correct.

2. Open the top cover and load the workpiece into the drum.

3. Close the lid, activate the drum switch and the heat switch for dehydration and drying.

4. After dehydration and drying, first turn off the drum switch and the heat switch, then use the foot to brake the brake plate to stop the drum completely.

5. Open the lid, lift the drum, and pour out the workpiece.

Product Parameters

| Material | SS304/ SS316L |

| Size | 80×100,Customized |

| Application | Chemical,eletcroplating field |

| Heating source | Electricity |

| Usage | For drying products after electroplating |

| Feature | Strong corrosion resistance and durability |

| Volume | According to your application performance |

| Warranty time | 1 year |

Key words:

Dryer

Video

Product video

Production line

Product video display

Video Display

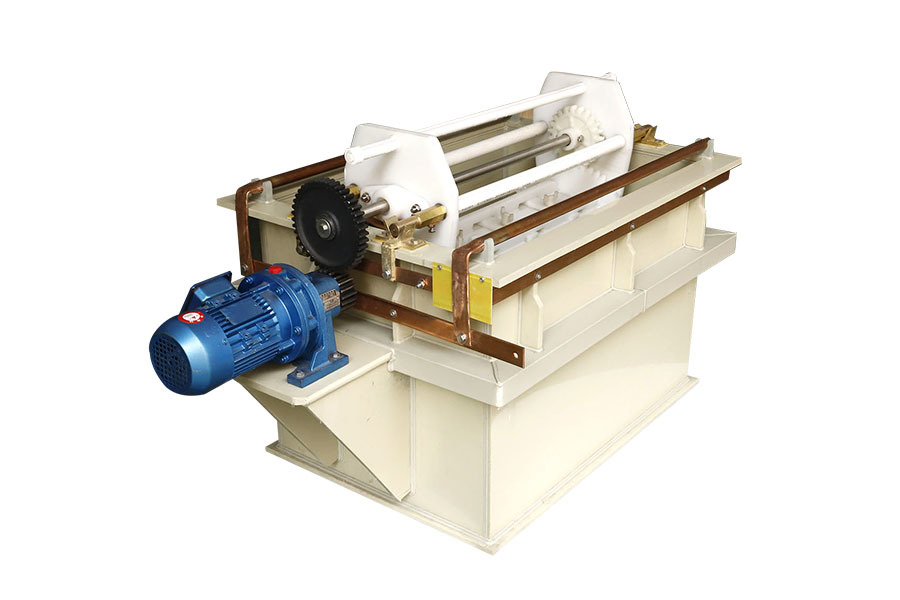

Factory Tour

Electroplating equipment

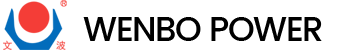

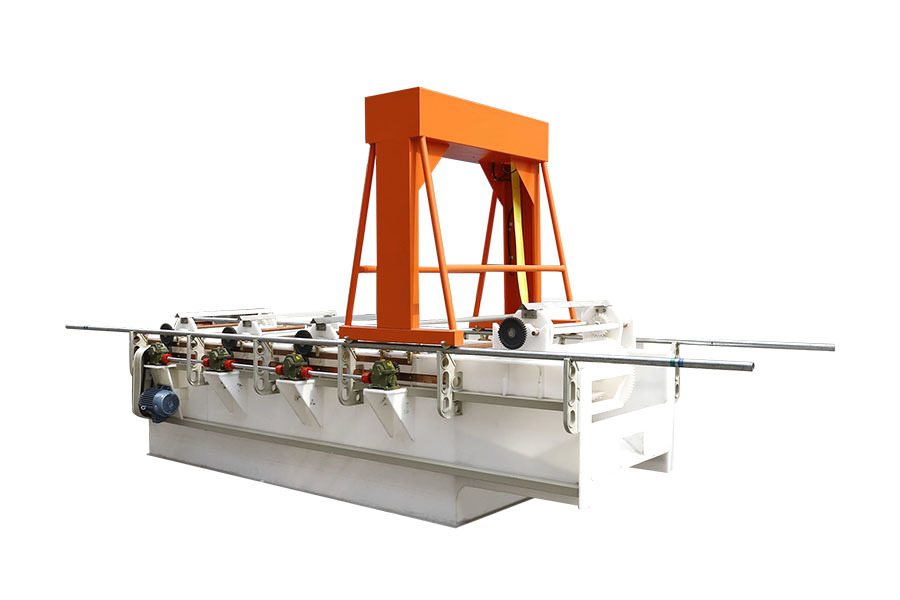

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

FAQ

How can I carry out my work if I plan to set up a new plating line?

What's the lead time for one project?

What is the necessary information you need for design?

We need plating machine for ×××, could you send me a quotation?

Related Products