PRODUCT

Filter

Electroplating solution, chemical liquid, pure water circulation filtration.

Classification:

Introduction

As ABS or hardware electroplating production lines require very high precision and high quality for filtering equipment. Especially for acid copper and nickel processes, our latest filter series SPF is a special filter for acid and nickel processes. It uses an integrated filter barrel and a pump with a cooling system. It can be combined with an intelligent control system to ensure the best filtering effect, and to ensure that there is no leakage of chemicals. Have CE/EMC certificate support.

Electroplating solution filter Uses and features

1. Chemical liquid circulation filtration process, PCB industry, electroplating industry, chemical industry, leather, wastewater treatment, etc.

2, high-precision filter, wide filter area, high efficiency, easy to operate, easy to clean.

3, the new one-piece design, sturdy and durable, never leak, high temperature and strong acid and alkali.

4, the new design, to change the shortcomings of traditional welding and lock teeth easy to leak, for the revolutionary technological innovation of the filter.

5, the filter material group vertical design, easy replacement of various components, and can be replaced at any time according to customer requirements.

6. Unique internal circulation pipe and detection port, effectively agitating the filter powder and the average surface pressure of the carbon powder for sampling and measurement, can prevent carbon leakage and ensure the quality of precision filtration.

7, standard equipment: flange and flange gasket, PVC screws, SUS screws.

Product Parameters

| Product Name | Electroplating filter |

| Material | PP raw material |

| Size | Full specification |

| Application | Electroplating solution, chemical liquid, pure water circulation filtration |

| Heating source | Electricity |

| Usage | Electroplating solution, chemical liquid, pure water circulation filtration |

Key words:

Filter

Video

Product video

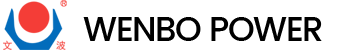

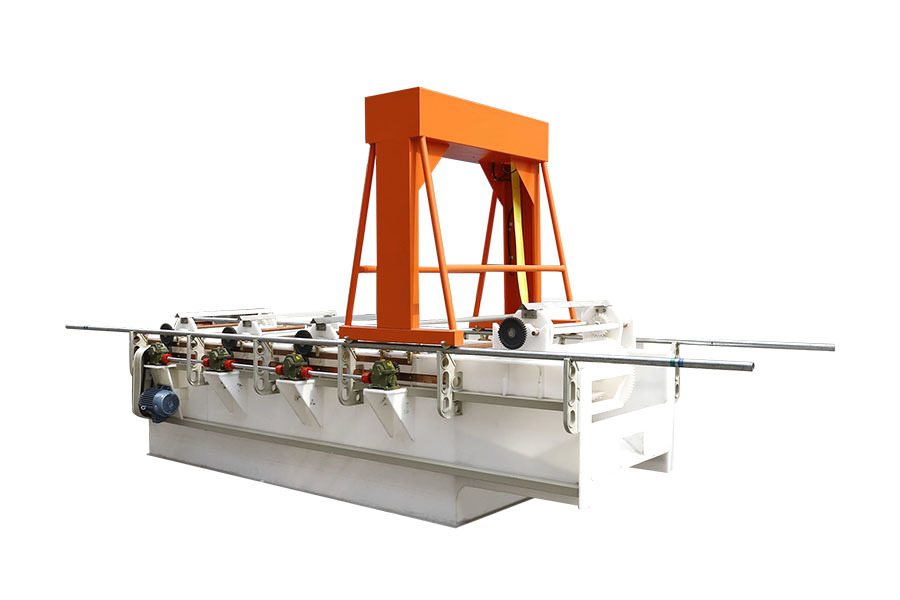

Production line

Product video display

Video Display

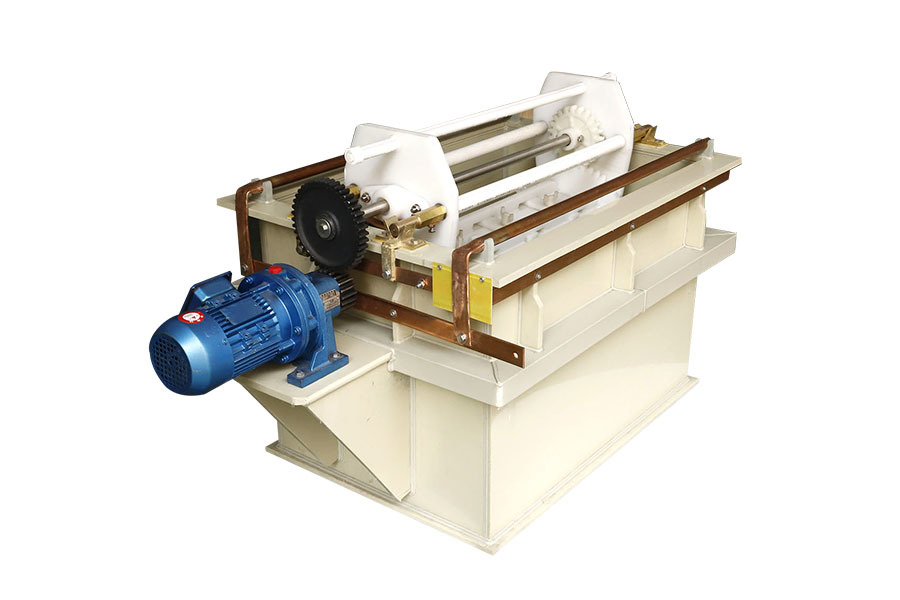

Factory Tour

Electroplating equipment

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

FAQ

How can I carry out my work if I plan to set up a new plating line?

What's the lead time for one project?

What is the necessary information you need for design?

We need plating machine for ×××, could you send me a quotation?

Related Products