PRODUCT

Waste Gas Treatment Equipment

PP spray tower is a new type of industrial waste gas treatment and processing equipment.

Classification:

Introduction

PP spray tower is a new type of industrial waste gas treatment and processing equipment. It is produced on the basis of an industrial exhaust gas purifier with a floating filler layer. It is widely used in the pretreatment of industrial waste gas treatment, dust removal, etc., and the purification effect is very good.

Product Information

Tower

Hardware electroplating, oxidation, cleaning production process using sulfuric acid, hydrochloric acid, nitric acid produced by acid gas has strong corrosive, acid fog treatment tower is an indispensable equipment for acid fog waste gas treatment.

Introduction

Acid fog treatment tower can also be called acid fog purification tower, acid fog purifier, acid fog washing tower, acid fog purification equipment, acid fog waste gas treatment tower, etc.

Usage

Acid mist treatment tower is mainly suitable for sulfuric acid, nitric acid, hydrofluoric acid, hydrochloric acid and other production processes in the process of acid/alkaline gas waste gas treatment equipment.

Working principle

1. The exhaust gas is collected by the air collector under the gravity of the fan and enters the lye washing tower.

2. Acid and base fog gas after impact washing, bottom-up through the packing layer circulation absorption;

3. The liquid is evenly sprayed in the packing layer through the spray, and flows down the surface of the packing layer into the circulating water tank.

4. Due to the continuous contact between the rising exhaust gas and the falling absorption liquid in the packing, the acid and base gas is captured by water, and the acid mist diameter is centrifuged or filtered out, and the gravity flows into the circulation tank through the tower wall.

Specification sheet

| Model | Air volume (m³/h) |

tower size(mm) | water tank size(mm) | Thickness (mm) |

pump power (kw) |

tuyere size(mm) |

| WB-ST600 | 1500 | φ600*2800 | 500*400*450 | PP-A/6 | 0.75 | φ200 |

| WB-ST650 | 2000 | φ650*3000 | 500*400*450 | PP-A/6 | 0.75 | φ250 |

| WB-ST800 | 3000 | φ800*3600 | 500*400*450 | PP-A/6 | 1.5 | φ315 |

| WB-ST900 | 4000 | φ900*3600 | 500*400*450 | PP-A/6 | 1.5 | φ315 |

| WB-ST1000 | 5000 | φ1000*3600 | 600*400*450 | PP-A/6 | 1.5 | φ400 |

| WB-ST1100 | 6500 | φ1100*3800 | 600*400*450 | PP-A/8 | 2.2 | φ400 |

| WB-ST1200 | 8000 | φ1200*4200 | 600*400*450 | PP-A/8 | 2.2 | φ450 |

| WB-ST1400 | 10000 | φ1400*4200 | 600*400*450 | PP-A/8 | 2.2 | φ500 |

| WB-ST1500 | 13000 | φ1500*4200 | 600*400*450 | PP-A/8 | 3 | φ500 |

| WB-ST1650 | 15000 | φ1650*4200 | 600*500*450 | PP-A/8 | 3 | φ600 |

| WB-ST1800 | 18000 | φ1800*4500 | 600*500*450 | PP-A/10 | 5.5 | φ650 |

| WB-ST2000 | 20000 | φ2000*4500 | 700*500*500 | PP-A/10 | 5.5 | φ700 |

| WB-ST2200 | 22000 | φ2200*4500 | 800*600*500 | PP-A/10 | 7.5 | φ800 |

| WB-ST2400 | 25000 | φ2400*5000 | 1000*600*500 | PP-A/10 | 7.5 | φ800 |

| WB-ST2600 | 30000 | φ2600*5000 | 1000*600*500 | PP-A/10 | 7.5 | φ1000 |

| WB-ST2800 | 35000 | φ2800*5000 | 1200*600*500 | PP-A/10 | 11 | φ1000 |

| WB-ST3000 | 40000 | φ3000*5000 | 1200*600*500 | PP-A/12 | 11 | φ1000 |

| WB-ST3300 | 45000 | φ3300*5500 | 1500*600*500 | PP-A/12 | 15 | φ1200 |

| WB-ST3600 | 50000 | φ3600*6000 | 1500*600*500 | PP-A/12 | 15 | φ1200 |

Key words:

Waste Gas Treatment Equipment

Video

Product video

Production line

Product video display

Video Display

Factory Tour

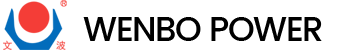

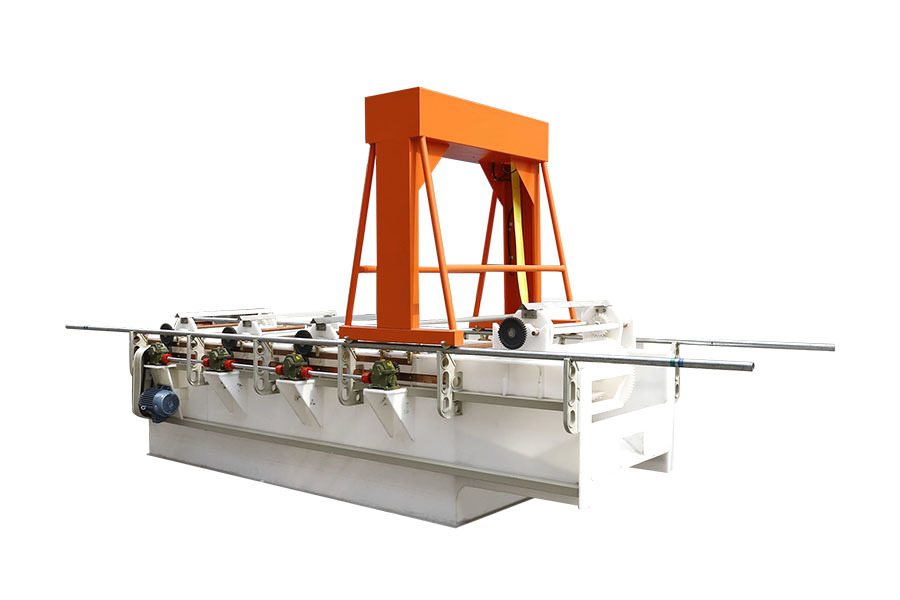

Electroplating equipment

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

FAQ

How can I carry out my work if I plan to set up a new plating line?

What's the lead time for one project?

What is the necessary information you need for design?

We need plating machine for ×××, could you send me a quotation?

Related Products