PRODUCT

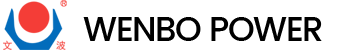

Semi automatic Roll Plating Chain Production Line

Hardware, relay, aerospace, automobile,precision instrument,clothing accessories,bags,clocks,glasses etc.

Classification:

Introduction

Main Components

Tank (PP/ PVC/ SS304/ 33316L)

Frame ( Metal with Powder coating)

Anode ( Copper )

Barrel, Motor, Sidewalk (FRP)

Water pipe system

Main Electric Device

Rectifier, Filter, Wastewater treatment machine

Cooling Machine, Dryer, Oven, Air compressor,

Waste gas treatment system.

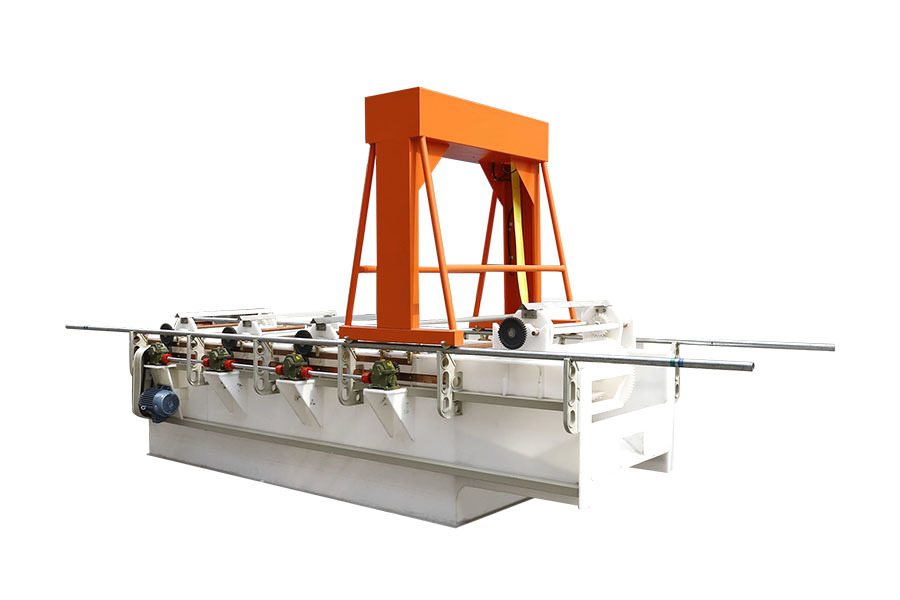

PP Tank

The plating tank is used to install a solution for zinc plating, copper plating, nickel plating, gold plating, anodizing, electrolysis, polish, and so on.

Gantry Crane

The gantry crane is equipped with an automatic turning device for the upper limit barrel. So that the barrel can continue to rotate after being lifted to ensure that the parts are drained.

Rectifier

High-frequency switching electroplating power supply is a device that provides power supply for electroplating, low-voltage electrolysis, aluminum anodizing, battery charging, and printed circuit board production. High-voltage dc multi-function power supply for electroplating, electrophoresis, water treatment, electro-etching, etc.

Product Parameters

| Item | Description |

| Material of tank | 15mm PP designed by different chemical solution or customers' requirements |

| Material of framework | Square steel tube, carbon steel with epoxy painting, stainless stell |

| Size | Customized |

| Delivery time | Differs from the sizes of line |

| Control system | PLC,computer control for DMS system |

| Heating mode | Electronic, steam, hot water |

| Mode of transporter | Automatic ,semi-automatic ,Manual |

| Accessory equipment | Rectifiers,filters,dryer,Ultrasonic machine,waste gas treatment system etc. |

| Warranty | 24 months |

| Application | Hardware, relay, aerospace, automobile,precision instrument,clothing accessories,bags,clocks,glasses etc. |

Key words:

Semi automatic Roll Plating Chain Production Line

Video

Product video

Production line

Product video display

Video Display

Factory Tour

Electroplating equipment

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

FAQ

How can I carry out my work if I plan to set up a new plating line?

What's the lead time for one project?

What is the necessary information you need for design?

We need plating machine for ×××, could you send me a quotation?

Related Products