PRODUCT

Hard oxidation power supply

Electroplating rectifier, electrolytic rectifier, oxidation rectifier, chrome plated rectifier, hard chromium rectifier, oxidation rectifier, metal electroplating rectifier, precious metal rectifier.

Classification:

Introduction

Since its establishment, the company has been focusing on cultivating its own brand and core technology, specializing in the design and manufacturing of surface treatment rectifier power equipment and high-frequency power supply fields. Its excellent product performance has received unanimous praise from partners. Our rectifier is widely used in various fields such as PCB electroplating, hardware electroplating, continuous electroplating, hard chromium electroplating, rare earth smelting, oxidation, electrophoresis, electrolysis, water treatment, etc.

In recent years, efforts have been made to increase research and development investment in the fields of power energy conservation, automation, and intelligence, striving to produce products that better meet market demand, providing high-quality products to users wholeheartedly, and making greater contributions to green environmental protection. The founder has 30 years of industry experience and has profound expertise in product research and development, design, and manufacturing. Adhering to the development concept of "integrity and win-win", with professional and rigorous scientific management, and perfect after-sales service, we have won the appreciation and praise of users, serving more than 10000 enterprises with a wide customer base. The company strictly implements the ISO9001 quality management system and has passed the CE safety certification. The implementation of networked and computerized management systems has formed a standardized and efficient modern management system.

High frequency electrolytic power rectifier is used for the electrolysis of non-ferrous metals such as aluminum, magnesium, zinc, lead, manganese, salt water, potassium salt electrolysis to produce caustic soda, copper foil, gold, silver, precious metal smelting, rare earth smelting such as neodymium iron boron, hard alloy diamond smelting, sewage, refractory material electric heating, carbon plants, graphitization furnaces, DC arc power supply, and other load properties of silicon carbide production. High frequency electrolytic power rectifier is used for the electrolysis of non-ferrous metals such as aluminum, magnesium, zinc, lead, manganese, salt water, potassium salt electrolysis to produce caustic soda, copper foil, gold, silver, precious metal smelting, rare earth smelting such as neodymium iron boron, hard alloy diamond smelting, sewage, refractory material electric heating, carbon plants, graphitization furnaces, DC arc power supply, and other load properties of silicon carbide production. High frequency electrolytic power rectifier is used for the electrolysis of non-ferrous metals such as aluminum, magnesium, zinc, lead, manganese, salt water, potassium salt electrolysis to produce caustic soda, copper foil, gold, silver, precious metal smelting, rare earth smelting such as neodymium iron boron, hard alloy diamond smelting, sewage, refractory material electric heating, carbon plants, graphitization furnaces, DC arc power supply, and other load properties of silicon carbide production.

Electrophoretic power rectifier, suitable for electrophoretic coating production lines and related technical requirements such as automotive electroplating, motorcycles, household appliances, metal shells, etc. The rectifier is a high-frequency power supply that uses high-performance filtering reactors to effectively suppress the harmonic components of the rectifier and meet the requirements of low-end output ripple output in electrophoretic coating production processes. It has a soft start function and can choose constant voltage method or constant current method according to process requirements. It has timing control and various protection functions.

Electroplating equipment * high-frequency power rectifier products: electroplating rectifier, electrolytic rectifier, oxidation rectifier, chrome plated rectifier, hard chromium rectifier, oxidation rectifier, metal electroplating rectifier, precious metal rectifier.

1. Hardware electroplating

(Plastic ABS electroplating, rolling plating, hanging plating, galvanizing, variegated, stainless steel electrolysis)

2. Precious metal electroplating

(Jewelry electroplating, laboratory filming, chemical factory filming)

3. Hard aluminum oxide power supply

(High power oxidation of profiles, oxidation of small parts, and hard oxidation of doors and windows)

4. Chromium plating electrolysis (reversing switch)

5. Electrolysis industry

(electrolytic stripping, electrodeposition, copper recovery, metal electrolysis, mineral leaching and extraction)

6. Electrophoretic industry (electrophoretic coating)

7. Water treatment power supply

(Water electrolysis, electrodialysis, electrocoagulation, electrolysis of hydrogen)

8. Continuous electrolysis industry (coil to coil electroplating, copper plating, nickel, zinc)

9. Plasma polishing (high-voltage polishing power supply)

10. PCB industry (PCB electroplating, adhesive residue removal power supply, nickel metal plating)

11. Goldstone power supply (grinding wheel, drill bit)

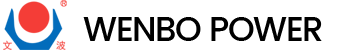

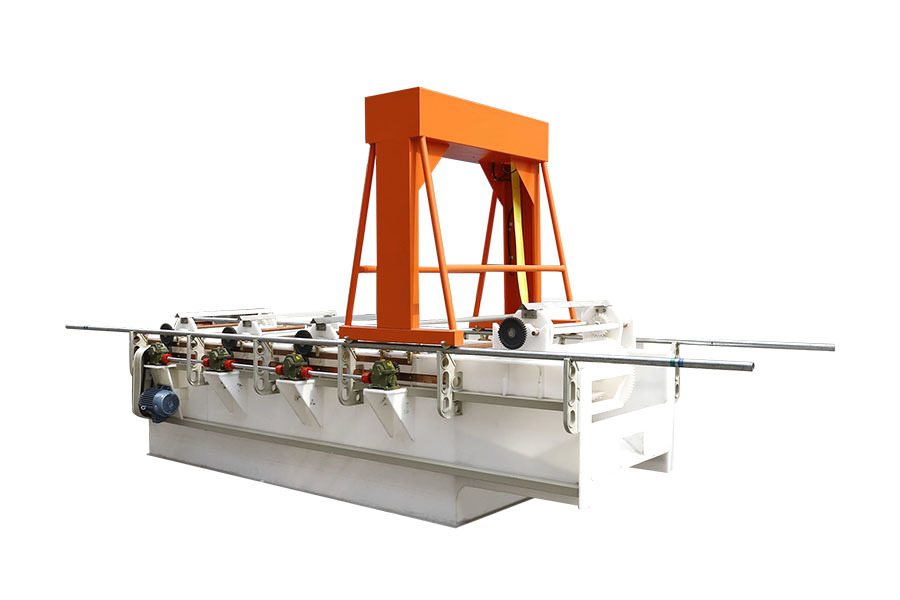

12. Intelligent swinging head, rotator, high-frequency oxidation power supply, oxidation rectifier

Oxidation rectifiers are mainly used in the fields of aluminum oxidation, anodizing, hard oxidation, micro arc oxidation, electrochemical polishing, oxidation coloring, and other oxidation surface treatment.

High frequency oxidation power supply (rectifier) - Our company has designed oxidation power supplies with different requirements for surface oxidation treatment processes of aluminum, titanium, magnesium and their alloy materials for you to choose from.

Key words:

Hard oxidation power supply

Video

Product video

Production line

Product video display

Video Display

Factory Tour

Electroplating equipment

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

Factory Appearance

FAQ

How can I carry out my work if I plan to set up a new plating line?

What's the lead time for one project?

What is the necessary information you need for design?

We need plating machine for ×××, could you send me a quotation?

Related Products